To get a general viscosity rating of a liquid, you can use a simple measuring technique. Now you know the centipoise rating of these fluids. Many of these products you probably use in your daily life. A rating of a higher centipoise is going to flow much slower. It is a unit of dynamic viscosity, the typical type of viscosity we think of.Ī fluid with a low centipoise will flow and move easily and fast. What is Centipoise?Ĭentipoise (CPS) is the viscosity value that is assigned to liquids. The measurement we use to describe the viscosity of a fluid is known as centipoise. While water-like, semi-viscous, and viscous are good terms to use sometimes you need to get more specific about the viscosity of a fluid. Viscous – Hair gel or pastes which are thick and do not move easily.Semi-Viscous – Maple syrup or soybean oil that is a bit thicker in nature.

#Low vs high viscosity free#

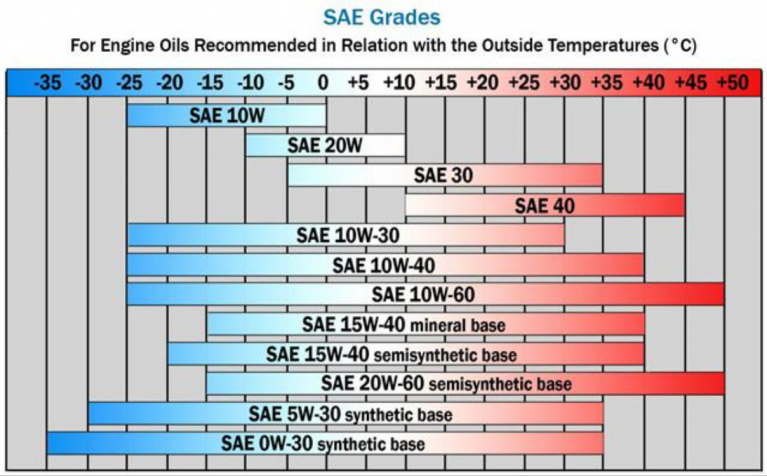

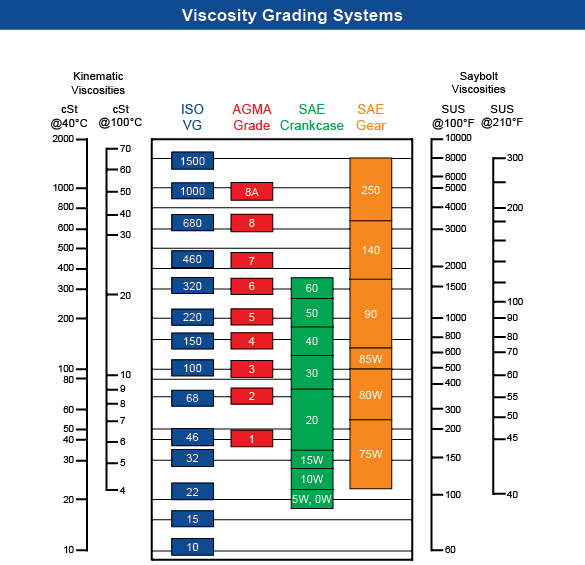

What causes viscosity is the cohesive forces between molecules in the fluid. For help and advice on choosing the right viscosity for your machinery please contact your nearest Anderol® distributor.What is viscosity? In simple terms, viscosity is a measure of a liquid’s resistance to flow, or the measure of internal friction. Selecting a lubricating oil of appropriate viscosity is essential to achieve optimum lubrication of equipment. These include oxidation, shear thinning, thermal degradation and many other common damaging conditions.Īny significant change of oil viscosity, either a reduction or increment, may damage lubrication film stability and effectiveness as shown in the table below: Reduction in viscosity The majority of the characteristics associated with wrong, contaminated or degraded lubricants will cause a change in viscosity. If the increase is sudden, a mechanical problem may be present in the compressor, or the oil may have been contaminated. An increase of more than 25% usually indicates that the oil should be replaced. Viscosity increase or decreaseĪssuming that no water is emulsified in the system reasons for a viscosity increase may be due to the oil having oxidized, an increase in pressure or decrease in temperature, contamination with a higher viscosity fluid, or evaporative losses of light oil fractions from high temperatures, glycol contamination and soot contamination. Viscosity values of lubricants are typically provided at 40 and 100 degrees Celsius. Similarly, a liquid becomes thicker when temperature drops. When temperature rises, a liquid becomes less viscous. Viscosity changes with temperature therefore the measuring temperature must be specified whenever the viscosity of a liquid is stated. The higher the VI value, the less the drop in viscosity as the oil warms up. The lower the VI, the more the drop in viscosity as the oil warms up. The viscosity index (VI) is the rate of change of viscosity between two temperatures. Using oil with the incorrect viscosity, whether too high or too low, can cause a range of issues with equipment. Instead, a machine’s viscosity requirement is based on such things as component design (i.e. Minimum, maximum and optimum viscosity requirements demanded by machines do not take temperature into account. Viscosity determines film thickness and film strength in machines. An oil of lower viscosity offers less resistance to the moving parts, but the oil can be easily squeezed out of the lubricating surfaces. However, the high internal friction of the oil may offer greater resistance to the movement of the lubricating parts. Oil with higher viscosity can withstand greater pressure without being squeezed out of the lubricating surfaces.

0 kommentar(er)

0 kommentar(er)